Welded Wire Basics

Banker Wire is the leading manufacturer of welded wire mesh in North America. Our dedication towards satisfying the customer fuels our focus on becoming your primary manufacturing partner. Specializing in small to large production runs, our manufacturing flexibility remains unmatched in the welded wire mesh industry. Banker Wire’s manufacturing culture ensures that our customers always receive the highest quality product with an unbeatable value.

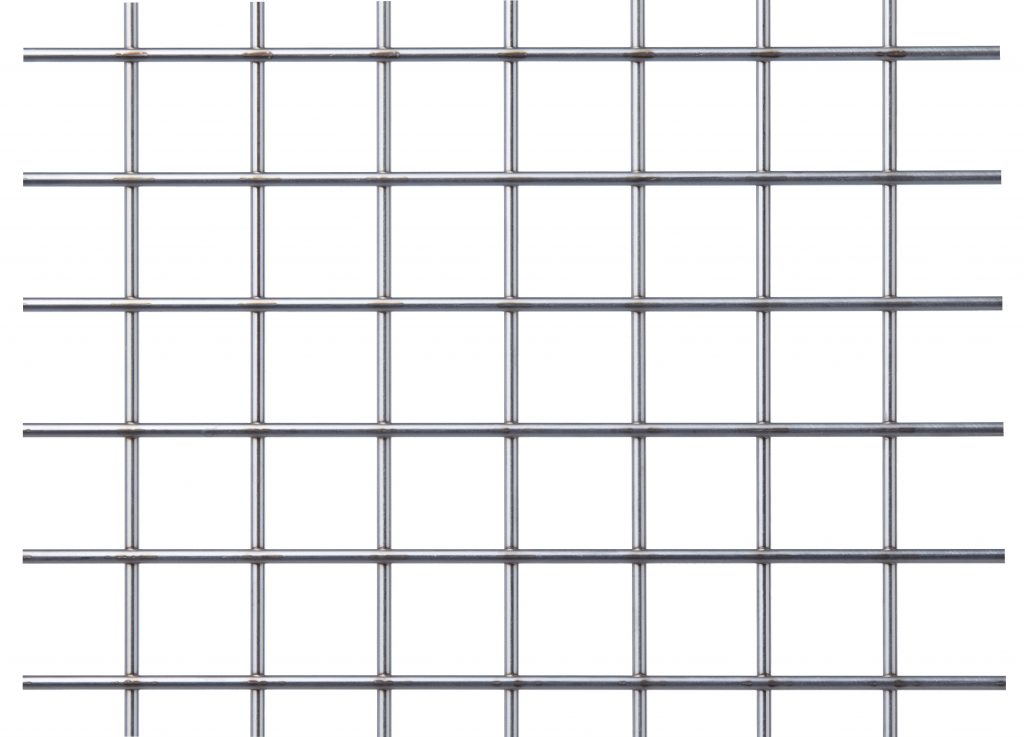

What is Welded Wire Mesh?

Welded wire mesh is constructed with two orthogonal wires that are joined together at their intersections using a resistance welding process to form a grid. The line wires of the grid are guided through the welder using a pattern board. The machine drops cross wires into place and fuses them together to create the two distinctive planes that form welded wire mesh.

At Banker Wire we currently utilize ten fully automated CNC grid welding machines and two CNC jig welders that allow us to produce to your exact specifications. Sheet sizes can be up to 78” wide and 240” long (dependent on mesh spacing). Wire spacing and diameter configurations are nearly endless, allowing us to be the top manufacturing partner for custom welded wire mesh.

Below in the next several sections of this page, you will find more detailed information on the basics of welded wire mesh and topics to take into consideration when ordering your specifications. Our knowledgeable staff is available to assist you with any questions you may have.

How Banker Wire Makes Welded Wire Mesh

Have you ever been curious about how welded wire mesh is made? Take a look at this video to fulfill that curiosity.

Line wires (also called long wires) are laid out on a pattern board to set the panel width spacing. Cross wires are fed into a hopper, and are programmed to be dropped one at a time onto the line wires. Then, the cross wires are resistance welded into place setting the panel length spacing. The panel advances after the weld and the process starts over again.

Manufacturing Capabilities

Banker Wire operates eight fully automated CNC grid welding machines and two CNC jig welders that can produce welded mesh to your exact specifications. With our machine variety we can produce small to large runs and specialty grids. Below are our capabilities:

Maximum Width Dimension: |

78″ |

Maximum Height Dimension: |

240″ |

Diameter Range: |

.105″-.375″ |

Spacing Range: |

Square Mesh = 1″ min. / Rectangular Mesh = 1/2″ x up to as needed |

Materials and Secondary Finishes for Welded Wire Mesh

Raw Materials: Welded wire mesh is utilized in a variety of settings that may require a high degree of performance in strength or corrosion resistance. Because of that, Banker Wire offers welded wire mesh in plain steel, pre-galvanized, stainless steel, galfan, and weathering steel. For more detailed information on these materials, please visit our Materials resource page.

Secondary Finishes: At Banker Wire, all of the products that we offer are manufactured in a bare, mill-finished condition. A secondary finish may be desired to protect the welded wire mesh, or to enhance a specific aesthetic. For welded wire mesh we can facilitate powder-coating, hot-dipped galvanizing, and decorative plating if desired.

Plain Steel

Pre-Galvanized

Stainless Steel

Galfan

Weathering Steel

Powder Coating

Hot-Dipped Galvanizing

Powder Coating

Hot-Dipped Galvanizing

Decorative Plating

Welded Wire Spacing

Welded wire mesh spacing can be expressed by measuring from the center of two wires (Center to Center) or by measuring the opening between two wires (Clear Opening). We can manufacture standard and custom welded wire mesh with a square mesh spacing range from 1” to as large as may be required. Rectangular mesh spacing ranges from 1/2″ x up to as long as may be required.

Welded Wire Diameter

Banker Wire manufactures welded wire mesh with a wide variety of wire diameters ranging from .105” to .375”. For accuracy, the wire diameter should be expressed in decimal format and not expressed as a gauge.

Edge Conditions

Banker Wire Welded Wire Mesh has two standard edge conditions: trimmed and untrimmed.

Trimmed: When ordering welded wire mesh with Trimmed Edges, wire overhang will be 1/8″ or less on three sides with Standard Heat Thumbnailing* on the fourth side. The final spacing around the perimeter may be reduced and balanced when necessary to stay within the dimension ordered.

Quality and Testing

Banker Wire manufactures to a strict set of internal standards that guarantee the welded wire mesh is produced to the highest possible quality and consistency. Throughout each production run, panels are checked for dimension, squareness, and strength to ensure that every panel meets our standards and is exactly the same as the one before it. The two tests shown below are used to check strength characteristics of our welded wire mesh.

Torque Test:

To ensure that there is a strong weld at each intersection, the operator will attempt to break that weld using a torque tool. The torque tool is calibrated per a set of internal standards but can also be calibrated to any requested standard. This test is performed at set intervals to verify consistency throughout the production run.

Weld Set-Down Test:

Weld-Set Down is a percent reduction in the overall thickness of the two wire diameters being fused together with an electric current. This test is performed to make certain that our welding machinery is functioning properly and consistently throughout the production run. A digital micrometer is used to record and store the height of the welded intersections across the width of the sheet.

Standard Measurements & Tolerances for Welded Wire Mesh

Banker Wire strives to manufacture the highest quality woven wire mesh on the market today. As there is a lack of ASTM standards for welded wire mesh, we have developed a set of standard measurements and tolerances for our welded wire mesh products. Our tolerances have been determined from historical product manufacturing and are being tested and improved upon constantly to ensure the best wire mesh possible.

An explanation of our measurements and tolerances can be found in the PDF download.