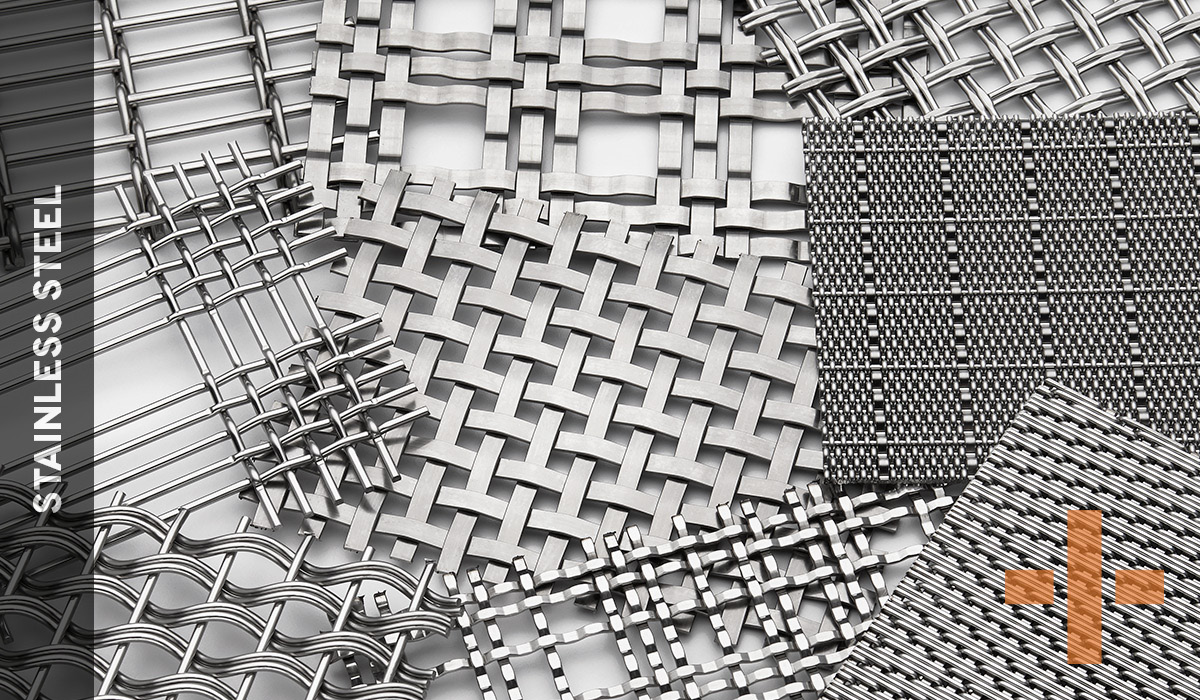

DS-5

Opaque Woven Wire Mesh Pattern

Pattern Details

Percent Open:0.0%

Overall Thickness:0.105

Crimp Style: PD4PZ

Aspect Ratio: 1.07:1

Opening Limitation: 0.000

Weight: 1.86 lbs./sq. ft.

Stainless Steel

Important Note Regarding Color

Please note that due to the limitations and relative inconsistencies of digital displays, the original and artificially colorized photography above is intended to only be a representation of the raw materials Banker Wire uses and is not a substitution for physical samples. Banker Wire manufactures all wire mesh in a bare mill finished condition. Please always confirm size, color, and finishes of wire mesh patterns with physical samples.

Additional Images

DS-5

Pattern Details

Percent Open:0.0%

Aspect Ratio:1.07:1

Weight:1.86 lbs./sq. ft.

Overall Thickness:0.105

Crimp Style:PD4PZ

Opening Limitation:0.000 in.

What are your dimensions?

We manufacture every job to size. List the dimensions and any addition details of your job. Please double check that your sizes and materials are within our Maximum Dimensions below.

Please double check that your sizes and materials are within our Maximum Dimensions below.

"Maximum" Dimensions of available raw material configurations

*Weight based on the specific density of mild (plain) steel **Maximum sphere diameter which will pass through opening Product specifications are subject to change. Product image is shown at 100% unless stated otherwise. For accuracy, specification sheet must be printed with no scaling. Measurements and data are approximate and should be confirmed with a physical sample.